Lithium carbonate lithium hydroxide packing and palletizing (二) the present situation of

Development of Lithium Carbonate Units in Major Domestic Manufacturers Tianqi lithium industry

At present, the full-load production of lithium carbonate in Tianqi Lithium Jet Flood Base has not yet been completed in Jiangsu Base. The company is actively promoting the technological improvement of Zhangjiagang Base in Jiangsu Province. It plans to stop production and overhaul in early May 2016. At the same time, it takes this opportunity to carry out technological transformation of key production links and devotes itself to improving production capacity and quality.

It is understood that Tianqi lithium industry has carried out adequate technical demonstration and pre-implementation preparations for the technical reform. During this period, some sections will start production ahead of schedule according to the situation. It is expected that the maintenance and technical reform will be completed by the end of May, and the whole line will resume normal operation. The goal of technological transformation is to expand the production capacity of Zhangjiagang Base to 1200 tons per month in June 2016 and to reach 1700 tons per year at the end of the year.

In addition, Tianqi lithium has announced publicly on April 23, 2016 the feasibility study of officially starting the annual production of 20,000 tons of battery-grade lithium hydroxide.

Tianqi lithium industry said that the reason for choosing lithium hydroxide is that according to the company's current production capacity, lithium carbonate products are in the majority; industry analysis report and market feedback show that the market share of lithium hydroxide as the basic raw material for lithium batteries has increased significantly in recent years, and will continue to show an upward trend in the future, but there are few enterprises that can produce battery-grade lithium hydroxide at present.

The design capacity of Tylison lithium concentrate is 740,000 tons per year, and it has not yet been fully produced. If the company's 20,000 tons of lithium hydroxide expansion plan is completed, Tylison chemical grade lithium concentrate can meet the needs.

Gan Feng lithium industry

As early as September last year, Ganfeng Lithium Co. invested $25 million in the initial period to acquire a 25% stake in RIM by acquiring part of the RIM equity held by Neometals Ltd and part of the capital increase in RIM. Ganfeng Lithium will hold 43.1% of RIM after the completion of the purchase of RIM 18.1% equity plan transaction.

On May 16, Ganfeng Lithium Industry said on the interactive platform of investor relations that RIM's annual production line of 200,000 tons spodumene concentrate is expected to start production in July (previously said to be put into operation in June, RIM is expected to supply 60,000-80,000 tons of lithium concentrate to Ganfeng Lithium Industry in 2016, which is now slightly delayed), basically meeting the company's demand for raw materials.

Tibet mining industry

Steyr

Previously, Steyr revealed on the interactive platform of investor relations that Hengxinrong has provided several customers with lithium carbonate samples for pre-sale, in preparation for market development after the 18,000 tons of lithium carbonate project was put into operation in 2016.

According to the data, Steyr is a large automotive parts manufacturing enterprise in Hubei Province. Its production and marketing rank in the forefront of the National Automotive bridge gear industry, and it is a member of Dongfeng Automobile Group. Jiangsu Steyr, a wholly-owned subsidiary of the company, used 153 million self-financing funds and two-stage capital-raising mode to increase capital and realize holding (51% equity) of Hengxinrong. The first 60 million capital-raising fund was paid in February 2015.

On July 27, 2015, Jiangsu Steyr paid Hengxinrong a second increase of 93 million yuan. The timely arrival of the second phase of the capital increase effectively ensures the smooth progress of Hengxinrong's annual production of 18,000 tons of battery-grade lithium carbonate.

Jiangte motor

It is understood that at present, Lithium Carbonate products of Jiangte Electric Machinery are mainly supplied to subsidiaries, and no long-term contract has been signed. At present, Jiangte Electric Machinery is speeding up the construction of the second phase lithium carbonate production line with an annual output of 6000 tons, which is scheduled to be completed by the end of this year.

Saline Lake stock

Qinghai Salt Lake Fozhao Lanke Lithium Industry Co., Ltd. (hereinafter referred to as "Lanke Lithium Industry"), a 51.42% subsidiary of Salt Lake Holdings, currently produces 10,000 tons of industrial lithium carbonate. Due to the high magnesium-lithium ratio (500:1 or even higher) of salt lake, which increases the difficulty of extraction, and the winter shutdown and other factors, the company's lithium carbonate plant did not reach production in 2015.

Salt Lake said that the company's production of lithium carbonate products in 2015 basically met expectations, producing 3,700 tons of lithium carbonate, has not yet reached production, 2016 will further increase production, is expected to meet production standards in 2017.

Rong Jie shares

When asked if there are plans to acquire other lithium resources in the future, Rongjie said that the company's mine is located in the methyl-carat mining area and there are no mining rights for lithium resources. The company's own lithium resources reserves are nearly 30 million tons, which can be exploited for nearly 30 years according to the scale of expansion. At present, the company's main task is to promote the re-production of the mine, and in the future, on the basis of doing a good job of existing lithium resources. Consider it again according to the timing and specific circumstances.

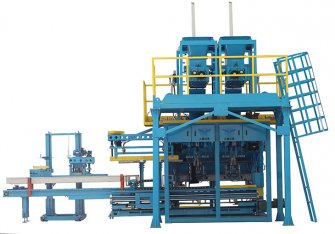

It is understood that Rongjie joint-stock mine resumption is currently coordinated by the local government, is progressing according to the plan; according to the local government's promotion plan, it is expected that the second quarter of mine resumption is more likely. Three-dimensional technology lithium carbonate packing and palletizing.

- Last:Lithium carbonate lithium hydroxide packing and palletizing (一) What is lithium carbonate

- Next:Type Selection of Lithium Carbonate and Lithium Hydroxide Packaging Machine Equipment

【Related Product】

- Full-automatic Packaging Machin

- Semi-automatic valve bag packin

- Semi automatic powder packaging

- SW-ATF-180 Fully Automatic Pack

- Semi-automatic Ton bag Packing

- Double hopper granule packing m

- Single hopper packing machine

- Semi-automatic packing machine

Safety record of Lu Gong net Number 37040202006018

Safety record of Lu Gong net Number 37040202006018