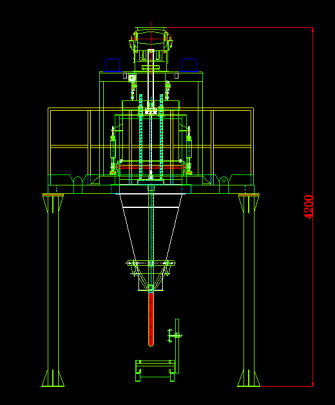

Batching machine

Introduction of DCS-P Belt Feeder for Batching Machine

DCS-P Batching Machine, accurate weighing, reliable operation, can achieve accurate quantitative feeding, can help users reduce waste of materials, improve product quality and automation of production process. It is specially used for continuous weighing and batching in cement, chemical and metallurgical industries. Equipment mainly includes: conveyor bracket, skirt ring belt, electrical control system, feeder controller, control cabinet, etc.

The working principle of DCS-P belt conveyor with Batching Machine:

The proportioning scale is also called weighing feeder, automatic proportioning scale, metering proportioning scale, quantitative feeder, quantitative proportioning scale, etc. Material silo enters the lower outlet through sieve mesh, and automatically falls into the belt through adjustable material flow door. The belt is skirt belt, which can prevent material overflow. The belt rotates at a uniform speed. Under the belt operation, the weight of material needed for proportioning is measured by weighing sensor. Through frequency conversion adjustment, the speed of proportioning scale is controlled, and the material is collected at the end of the belt. The section is put into the grain warehouse of the packing scale, and the scraper is arranged under the belt of the outlet and outlet, so as to clean up the attachment of the belt and improve the proportioning accuracy.

Functional Characteristics of DCS-P Belt Feeder with Batching Machine

The belt conveyor uses I-beam as main support frame and channel steel as support leg, which has high integrality and good stability. The belt anti-deviation switch is installed on both sides of the main support frame to prevent the belt from deviating. The unique integral design makes the ring belt never deviate. The driven drum is equipped with a screw tensioning device.

Unique skirt tape can prevent material from overflowing to both sides, while avoiding material accumulation at the head and tail drum, so as to achieve the best weighing state.

The feed inlet is equipped with a material flow gate to adjust the thickness of the material layer.

Technical parameters of DCS-P belt conveyor for Batching Machine

| Belt Width(mm) | Reduction Motor Model (SBD50.65 Series) | Belt Line Speed(m/s) | Load Sensor (kg) | Rated Speed of Frequency Converter(hz) | Hourly Output(t/h) | Reference Hourly Output (t/h) |

| 650 | SBD65-923-1.1KW | 0.0082 | 50 | 50 | 0.1-1.0 | 0.2-0.8 |

| 650 | SBD65-923-1.1KW | 0.0254 | 50 | 50 | 0.4-4.0 | 0.65-3.2 |

| 800 | SBD65-923-1.1KW | 0.0632 | 100 | 50 | 2.0-20 | 4.0-16 |

| 800 | SBD65-923-1.1KW | 0.1539 | 100 | 50 | 4.0-40 | 10-32 |

| 1000 | SBD65-923-1.1KW | 0.1725 | 100 | 50 | 10-100 | 40-80 |

| 1200 | SBD65-923-1.1KW | 0.2661 | 200 | 50 | 16-160 | 80-120 |

Instructions for ordering DCS-P belt conveyor for Batching Machine:

1. Material name, material characteristics, material types, such as shape, performance, water content, fluidity, temperature, etc.

2. Accurate flow range: (minimum flow) t/h to (maximum flow) t/h, commonly used flow t/h.

3. Required output: daily output or daily output.

4. Control Accuracy: Requirements for Weighing Accuracy.

5. Other requirements of Batching Machine.

-

You may be interested in: automated batching system

-

Recommended Solution: Batching System Solution

【Related Product】

- Bulk Full-automatic Loading Machine

- Pallet Full-automatic Loading Machine

- Ton Bag Full-automatic Loading Machine

- Small Bag Full-automatic Loading Machine

- Fully Automatic Bulk Bag Packaging Machine

- SW-JP-F-25 pumping type vibration feeding packaging machine

- Full - automatic packaging machine for organic fertilizer

- Valve Packing Machine/Scale

【Relevant Articles】

- Application Characteristics of Potassium Dihydrogen Phosphate Full-auto

- How to Select the Type of Full-automatic Ton Bag Packing Machine for Co

- Selection of Automatic Packing Machine for White Granulated Sugar Produ

- Detection and anticorrosion of electrical components of automatic packi

- Requirements of Full-automatic Ton-bag Packing Machine for Ton Bags

- The selection and application of potassium tert-butyl alcohol in automa

- Zaozhuang Sunweigh teaching you how to choose packaging machine

- Leadership of the municipal government to visit Zaozhuang Sunweigh Tech

Safety record of Lu Gong net Number 37040202006018

Safety record of Lu Gong net Number 37040202006018