Automatic batching system

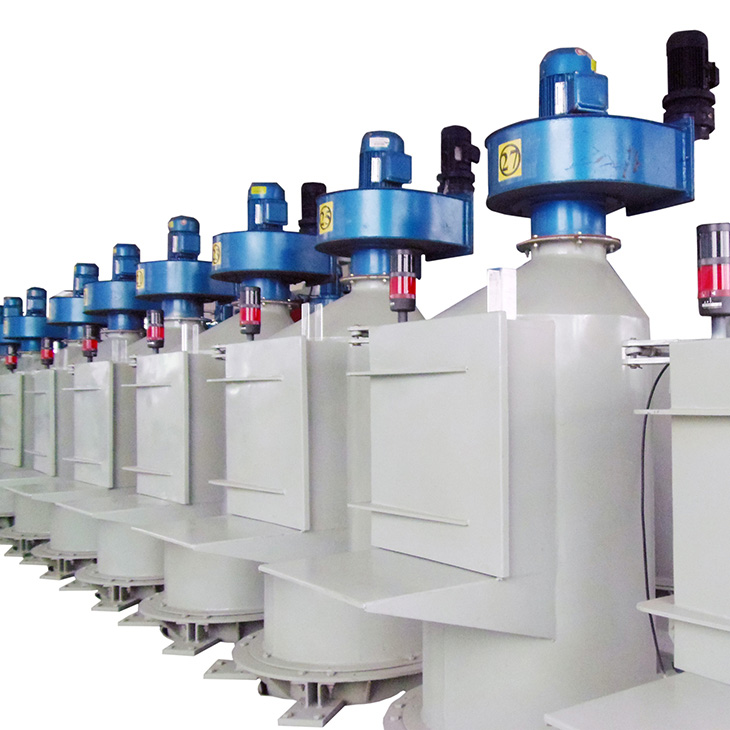

Introduction of automatic batching system/automatic batching production line/automatic weighing and batching system:

Automatic batching system is a kind of automatic batching equipment used in industrial production. It is usually controlled by a computer with automatic batching algorithm software. Automated batching system can control many scales at the same time, many kinds of different materials or control output operation intuitive, clear and automatic recovery function; powerful report function, can record and store a large number of data and tabulation printing; good reliability; powerful alarm function, can reduce the waste rate to the lowest level; with online automatic monitoring software, through real-time online monitor, Monitor important production information at any time.

Zaozhuang Sunweigh Technology Co., Ltd. has been devoted to the design and development of automatic proportioning system. The developed friction material automatic weighing proportioning system, new building material proportioning system, soil conditioning agent proportioning system, SiC automatic proportioning system, briquette proportioning system are widely used in various industries and have received unanimous praise. The automatic proportioning system consists of error prevention, feeding layer, proportioning and conveying layer, control system, mixing layer and packing layer.

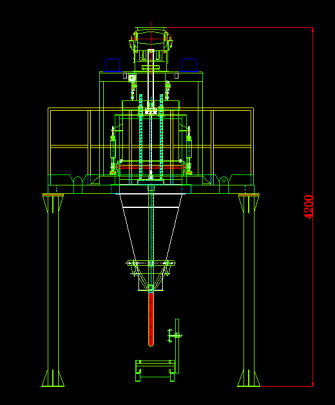

The size and material of the warehouse for error prevention and feeding layer are designed according to the material condition. The warehouse is divided into three specifications according to the requirement in order to control the precision and feeding frequency better. The warehouse can choose stainless steel or carbon steel according to the cost and service life. The material in the warehouse is separated from the outside air, and each warehouse has a warehouse door, which keeps closed and reduces the material. Contact with the outside world to avoid material being affected by humid air; Bar code identifies feeding errors and prevents materials from being mistakenly fed; original information used in batching can be traced back to avoid material mixing; single dust removal system is set up on the top of warehouse, and customers can choose single dust removal on the top of warehouse or uniform dust removal by pipeline according to their needs to reduce material losses. The automatic batching system adopts horizontal spiral variable speed feeding mode, adopts big Jiaolong accelerating mode to ensure feeding speed, adopts small Jiaolong slowly adding mode to ensure feeding accuracy, and installs 40*40 diameter 5 mm stainless steel welding screen in the silo to filter impurities or agglomerated materials of raw materials; equips with material level alarm device, which can carry out small batching as an independent material. System operation.

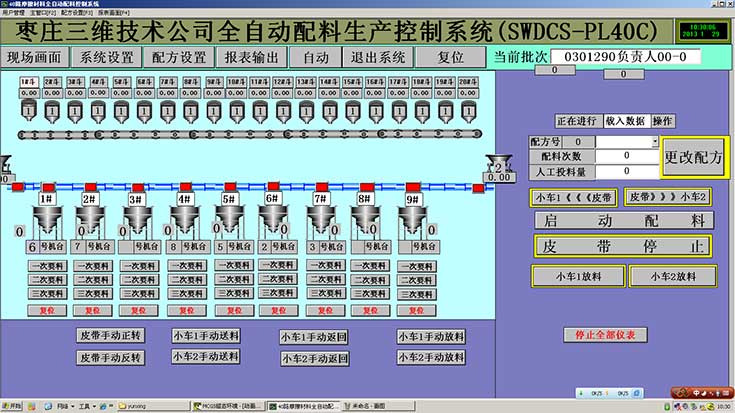

The proportioning conveying layer and the control room are placed in the proportioning and conveying layer of the second layer, so that operators can monitor the proportioning site and adopt belt conveying mode, rail trolley conveying mode, belt conveying mode combined with rail trolley conveying mode. Belt conveying mode is mostly used for material proportioning with large production capacity, fast proportioning speed, V-belt structure, reducing contact with materials, and equipped with material brushes at both ends of the belt in order to clean up the material adhering to the belt; the proportioning system is synchronized proportioning, the material can be put into the belt in the conveyor to make the operation, the belt is equipped with sensors, and has the function of double weighing, the proportioning time is less than 3.5 minutes. Railway trolley conveying mode is mostly used for material proportioning with low output, high proportioning accuracy, no stainless rigid material contact between the receiving vehicle and the material, the receiving vehicle is equipped with dust collector, the weight instructions and feeding sequence of the proportioning are from the computer setting program, the receiving vehicle adopts servo control, and the encoder feedback data and proximity switch double control, so as to achieve the fast and fast collection speed. Correct alignment, ingredient time is less than 5 minutes. Belt and rail trolley combined conveying mode, mostly used for the larger production and the number of mixers more ingredients; after the ingredients are qualified, all materials fall into the belt synchronously, the belt rotates to convey the material to the trolley, and the trolley conveys the material to the mixer of system instructions. The equipment has the commonness of belt and trolley conveying mode, and the ingredient speed is fast, which can meet the requirements of 2-9 mixers. Use of the machine.

DCS control system is adopted in the control system, and the pneumatic, stopping and running of the whole system are controlled and monitored in the control room; the whole equipment is equipped with a fault detection system, the back equipment is broken down, the front equipment is stopped by itself, and the position and cause of the fault point are displayed, and the operation state of the system is displayed by an alarm lamp; the control mode adopts three-level control mode: upper position PLC batching instrument. Table. The control interface is simple and clear, with animation displaying the batching process and batching data, which is clear and eye-catching. The control room personnel communicate with the on-site personnel through the walkie-talkie.

Mixing and loading layers, mixing time and mixer linkage; accurate packing is easy to trace.

Functional characteristics of automatic batching system/automatic batching production line/automatic weighing and batching system:

1. The automatic batching system has the advantages of fast batching speed and high accuracy: the batching process is controlled by intelligent instruments, which improves the batching efficiency by 20 times, and the whole batching process can be completed within 30S. Each batching process has no influence on each other, ensuring that the accuracy of each batching is less than 0.2%.

2. The automation degree of automatic batching system is high: IPC+PLC is used to centralize the whole process and can run many kinds of formulations at the same time. According to the setting, the system can automatically select and switch the formulation, allocate the silo, and intelligently adjust the secondary feeding. It realizes the unmanned operation, automated production and intelligentized operation of the whole process of feeding-batching-conveying-discharging-mixing-discharging. 。

3. Automated batching system operates in a variety of ways to meet the requirements of different batching processes: the production process can choose manual, semi-automatic, full-automatic and other different modes of operation, which can achieve complete automation operation, and can also be guided semi-automatic operation under human intervention.

4. Automated batching system has strong scalability: the system can support 10 mixers running at the same time. If the production line needs to increase production capacity, only adding mixers on the basis of the original system and setting up corresponding equipment on the upper machine system can complete the expansion of production capacity.

5. Automated batching system has strong adaptability: the system uses a number of patented technologies to optimize the batching process, which can meet the requirements of raw materials with different physical properties.

6. The equipments of automatic batching system are well matched: feeding system, transport trolley, storage warehouse, dust collector and other equipments are directly and seamlessly connected, and the whole process is dust-free and accurate.

7. Automated batching system is safe and reliable: the system uses well-known brand components at home and abroad as the design carrier, and adopts advanced process settings to manufacture, which is safe and reliable.

8. Complex ingredients such as friction materials and refractories in automatic batching system can be designed according to requirements.

Application case of automatic batching system/automatic batching production line/automatic weighing and batching system:

---Fujian Guanliang Automobile Parts Industry Co., Ltd. - 40 Road Automatic Batching System

- Hangzhou Feiying Automotive Parts Co., Ltd. - 40 Road Automatic Batching System

Fujian Huatai Auto Parts Co., Ltd. - 20 Road Automatic Batching System

Zhuhai Glelli Group - 28 Road Automatic Batching System

- Zhuhai Glelli Group - 46 Road Automatic Batching Systems

- Liangshan Hengtong Industrial Co., Ltd. - 30 Road Automatic Batching System

Iranian Customer-30 Route Automatic Batching System

- Shanghai Huaxin Friction Material Co., Ltd. - 30 Route Automatic Batching System

- Hangzhou Anet Industrial Co., Ltd. - 36 Road Automatic Batching System

- Gansu Qilian Mountain Youan Brake Material Co., Ltd. - 28 Route Automatic Batching System

- Liangshan Neichi Automotive Parts Co., Ltd. - 24 Road Automatic Batching System

Algerian Customer-20 Automatic Batching System

JIANGSU ANJIE AUTOMOBILE PARTS CO., LTD. - 2 pre-press weighing scales

- Changchun Tebick Shili Automobile Parts Co., Ltd. - 1 Press Form Pre-Measuring Scale

QINGDAO JIHONG AUTOMOBILE PARTS CO., LTD. - 1 Sub-loading Scale

Chongqing Aoshunte Machinery Manufacturing Co., Ltd. - 2 Press Form Pre-weighing Scales

Chongqing Yihua Technologies Co., Ltd. - 1 Pressure Pre-weighing Scale

- Meizhou Golden Forest Industrial Co., Ltd. - 4 Press Form Pre-weighing Scales

Chongqing Wangcheng Friction Material Co., Ltd. - 2 Press Form Pre-weighing Scales

Qingdao Henghua Automobile Parts Co., Ltd. - 1 Packing Scale

- Zhuhai Glelli Group - 1 Packing Scale

SHANGHAI HUAXIN FRICTION MATERIALS CO., LTD. - 2 separate weighers

- Hunan Boyun Group - 2 sub-loading scales

Video case of automatic batching system/automatic batching production line/automatic weighing and batching system

-

You may be interested in: batching scale

-

Recommended Solution: Batching System Solution

【Related Product】

- Bulk Full-automatic Loading Machine

- Pallet Full-automatic Loading Machine

- Ton Bag Full-automatic Loading Machine

- Small Bag Full-automatic Loading Machine

- Fully Automatic Bulk Bag Packaging Machine

- SW-JP-F-25 pumping type vibration feeding packaging machine

- Full - automatic packaging machine for organic fertilizer

- Valve Packing Machine/Scale

【Relevant Articles】

- Application Characteristics of Potassium Dihydrogen Phosphate Full-auto

- How to Select the Type of Full-automatic Ton Bag Packing Machine for Co

- Selection of Automatic Packing Machine for White Granulated Sugar Produ

- Detection and anticorrosion of electrical components of automatic packi

- Requirements of Full-automatic Ton-bag Packing Machine for Ton Bags

- The selection and application of potassium tert-butyl alcohol in automa

- Zaozhuang Sunweigh teaching you how to choose packaging machine

- Leadership of the municipal government to visit Zaozhuang Sunweigh Tech

Safety record of Lu Gong net Number 37040202006018

Safety record of Lu Gong net Number 37040202006018