Ton Bag Packing Machine

Product Introduction of Ton Bag Scale/Ton Bag Packing Machine

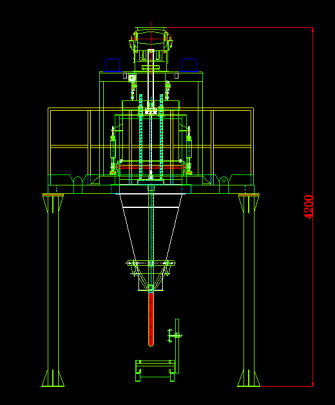

Ton bag packing machine is also called ton bag packing machine or big bag packing scale. It is an automatic packaging machine that packs 500KG - 2000KG each time. According to the proportion and characteristics of materials, the weight of each packaging is different. Normally, it will not be less than 500kg or more than 2000kg. Because the mechanical structure of the ton-bag packaging machine is fixed, regardless of the material performance, the volume of each bag is basically the same, and the material with a large proportion is basically about one cubic meter, that is, the weight is heavier, generally between 1.5 tons and 2.5 tons, and the fine powder with a small proportion is generally about one cubic meter, and the weight is lighter, generally between 500 kg and one ton.

According to the different material performance, the feeding mode of the ton-bag packaging machine is different: the material with good fluidity is fed by gravity, and automatically flows into the ton-bag through the weight of the material itself; the powder material is fed by screw, the advantage of screw feeding is to prevent the material from punching and to let the material evenly enter the bag; the mixture material is fed by leather. Easy-to-bond materials are usually fed by vibration.

The gross weight type weighing is used in all the ton bag packers. No weighing bucket is needed, and the materials are directly put into the packing bags. According to the difference of tonnage bags, the lifting lugs of tonnage bags scale have four lifting lugs and two lifting lugs. If a ton bag has an inner bag, the general ton bag packer needs to have the function of blowing the bag. That is, before the material enters the bag, the inner bag in the bag is blown up to prevent the material from entering the bag and forming a dead corner, so that the inner bag can not be fully packed or torn. The large bag packing scale of powder material also needs to be equipped with dust removal mechanism to collect the dust generated during the process of packaging and feeding, so as to keep the environment clean and environmental protection.

According to the position of the weighing sensor, the automatic tonnage-bag scale can be divided into two types: the upper weighing mode and the lower weighing mode. Ton bag packers are usually equipped with conveyors to transport qualified bags through conveyors so that cranes and forklifts can remove the bags. Advantages and development trend of ton-bag packaging machine: more and more finished materials are packed in large bags, which can save packaging costs and lower packaging and handling costs; large bags are gradually promoted in industrial use, while small bags are mainly used in civil use. Small bags will gradually be replaced by large ones. Our company's main products are DCS-1000-DG-W ton bag packing machine and DCS-1000-DN-T ton bag packing machine.

DCS-1000-DN-T Packaging Process and Functional Characteristics of Ton Bag Packaging Machine:

1. Hanging bags: artificially hang four lifting bags of bags onto the hook of the ton bag packing machine, then start the start button. After receiving the start signal, the control system detects the preparation of the system, and then detects the voltage, pressure, dust removal and weight data in turn. If the whole system is in normal condition, the lifting cylinder starts to work, and the bags are raised to a certain height, and the system detects them. When the packaging bags are in place, the feeding mechanism is started to transport the materials from the warehouse into the packaging bags and start the packaging process.

2. Weighing process: Because the gross weighing is adopted in the weighing scale of ton-bag, after the bag is lifted to a certain height, the system treats the bag and the whole lifting mechanism and sealing mechanism as zero position, so as to ensure that the net weight of the material entering the bag is zero. After clearing, according to the characteristics of the material and packaging bag, the system opens the process and function of blowing, dust removal, lifting and placing the bag and vibration bag.

3. Packaging bag conveying: when the material in the package is close to the set target weight, the feeding speed of the feeding mechanism decreases and the feeding quantity decreases to ensure the packaging accuracy; when the package weight reaches the set weight, the system stops feeding, and at the same time lifts the package bag and drops the pneumatic power, puts the package bag on the conveyor, and the lifting lug turns over under the action of the bag cylinder, and pushes out the lifting belt of the package bag. Hook, packaging bags automatically fall off; conveyor starts to start and deliver the packaging bags to the bottom of the ton bag packaging machine, so as to complete the packaging process of a ton bag.

4. Fully automatic tonnage bag scale is also a semi-automatic packaging machine, which needs manual bagging. The rest of the process is fully automated.

5. For imported materials such as feed and food, it is generally necessary to install metal detectors and removal mechanisms at the entrance of packaging bags to remove the fine metals in the materials so as to prevent metal from causing harm to human beings and livestock.

6. According to the actual needs, the system has two modes of automatic and manual operation, and can be switched at will, without affecting the stability and packaging accuracy of the system.

7. There are many kinds of conveyors matched with the ton bag packing machine: Calla Lily conveyor, belt conveyor, chain conveyor, roller conveyor, conveyor trolley, etc.

8. The accuracy of general packing machine is 0.2%. The accuracy of ton bag packing machine can generally reach 0.1%-0.05%, or even higher.

Technical parameters of DCS-1000-DN-T for ton bag packing machine:

Model Specification: DCS-1000-DN-T

Weighing range: 500-2000 kg

Weighing accuracy: 0.1% F, S

Weighing speed: 25-40 bag/h

Air consumption: 9m³/h

Power supply: AC380V 50Hz

Power: 3.7 kw

Air pressure: 0.5-0.7 Mpa

Sensor Form: Upper Sensor

Purchasing essentials of ton bag packing machine:

Purchase a set of fully automatic ton-bag packaging machine to meet the needs, first of all, to have an accurate understanding of their own material properties, if it is particulate material to determine the flow of materials, specific gravity, according to the product line to determine the end of the package ton less bags to meet the requirements. If it is powder material, first of all, it is necessary to determine the moisture content, gas content, the number of materials, whether the material is easy to melt and decompose, whether it needs anti-corrosion and explosion-proof, whether the material is easy to block, punch and Bridge in the packaging process; if it is super-new powder material, it is necessary to install a vacuum system to remove the excess gas in the material after packaging; if it is super-new powder material, it is necessary to lift the finished product bag after packaging. If lifting by traveling crane, it is necessary to use conveyor to transport the ton bag from the bottom of the ton bag packer. If the bag is shoveled or lifted by forklift truck, the ton bag can be lifted directly under the ton bag scale without conveyor.

1. First confirm the installation location and size.

2. Determining material characteristics and properties

3. Confirm the particularity of the environment, whether it is explosion-proof, explosion-proof grade, gas explosion-proof or powder explosion-proof.

4. Transport mode of finished packing bags

5. Size of packing bags and number of slings

6. Packing output, how many bags to pack per hour

-

You may be interested in: automatic packing scale ton bag packing scale

-

Recommended Solutions: Powder Material Quantitative Packaging Machine Solutions Mixed Material Packaging Machine Solutions Particle Packing Scale Solutions

【Related Product】

- Bulk Full-automatic Loading Machine

- Pallet Full-automatic Loading Machine

- Ton Bag Full-automatic Loading Machine

- Small Bag Full-automatic Loading Machine

- Fully Automatic Bulk Bag Packaging Machine

- SW-JP-F-25 pumping type vibration feeding packaging machine

- Full - automatic packaging machine for organic fertilizer

- Valve Packing Machine/Scale

【Relevant Articles】

- Application Characteristics of Potassium Dihydrogen Phosphate Full-auto

- How to Select the Type of Full-automatic Ton Bag Packing Machine for Co

- Selection of Automatic Packing Machine for White Granulated Sugar Produ

- Detection and anticorrosion of electrical components of automatic packi

- Requirements of Full-automatic Ton-bag Packing Machine for Ton Bags

- The selection and application of potassium tert-butyl alcohol in automa

- Zaozhuang Sunweigh teaching you how to choose packaging machine

- Leadership of the municipal government to visit Zaozhuang Sunweigh Tech

Safety record of Lu Gong net Number 37040202006018

Safety record of Lu Gong net Number 37040202006018